Proactive Pest Management

Helps Pasta Plant Save Big

THE SITUATION

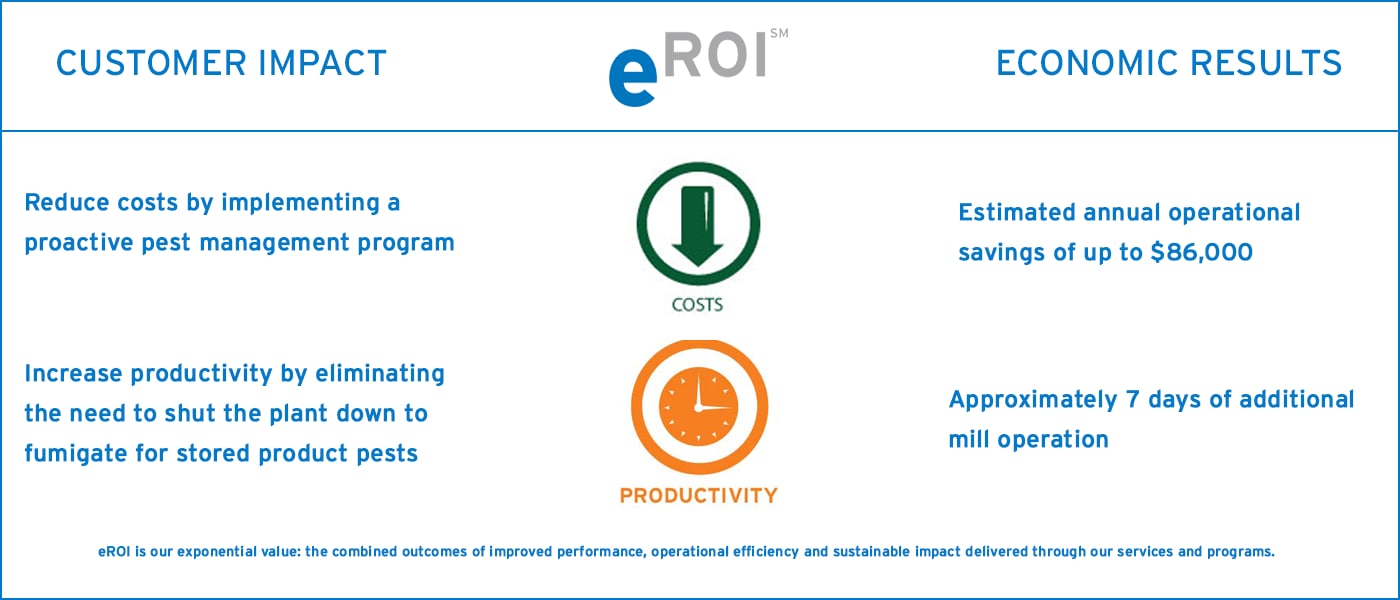

A privately-held pasta company in the U.S. was performing annual structural fumigations to knock down the population of confused flour beetles and warehouse beetles that was invading the facility. The cost of these fumigation procedures was running approximately $190,000 a year. In addition, the fumigation treatments required the mill to shut down for one week which added to the expense. They needed to cut costs without taking a hit on their reputation.

Ecolab and the company were able to drive down pest activity and save over $86k each year.

THE SOLUTION

Together, Ecolab and the customer implemented a proactive stored product pest program. The program included:

- Setting up over 300 monitors to determine the source of pest activity

- Providing recommendations on how and where to properly clean to help prevent pests

- Tracking against pest activity thresholds to manage against these pests

- Performing regular residual treatments to prevent activity

In addition to the regular program, yearly pest prevention training was provided to the QA Manager and the plant staff to prevent pest activity. The training showed the importance of prevention tactics including proper sanitation procedures, correcting structural issues that can cause pests to enter and harbor inside; and identifying operational inefficiencies like proper product rotation practices.

THE RESULTS

By implementing the proactive Stored Product Pest program, Ecolab and the company were able to drive down pest activity and eliminate the need for structural fumigation procedures. The company has experienced a reduction in the number of customer complaints and the plant has saved over $86k each year.

Related Stories

Visitors who viewed this story also viewed