Phosphate Mining

Improving Outcomes in Phosphate Processing

Solving for Fertilizer

Nalco Water is Your Premier Partner for Every Stage of the Phosphate Mining Process

Phosphate beneficiation relies on a carefully balanced process that considers the impact of each stage on the next. Your phosphate beneficiation process is unique and requires a chemistry program that considers safety, profitability, efficiency and product quality at all stages while helping to sustain the surrounding environment.

Nalco Water offers a comprehensive suite of solutions that can be customized to fit your needs. We offer phosphate rock beneficiation, phosphoric acid and fertilizer production programs that optimize the phosphate flotation process (both reverse and direct) for maximum recovery. Our advanced scale control solutions help reduce the amount of downtime needed for scale cleaning. By choosing the appropriate partner, you can significantly improve the recovery and grade of the end fertilizer product while maintaining productive performance and sustainable chemistry.

Delivering Economic and Environmental Value

Nalco Water is a partner that delivers economic and environmental value. By focusing on the entire phosphate mining process, we help increase yield, grade and recovery as well as improve asset life, asset utilization and safety. And we do it all while conserving energy, water and raw materials. Using our suite of phosphate beneficiation solutions, our approach results in optimized productivity and throughput, which can positively impact our customers' bottom line. We use decades of industry experience, innovative technologies, local on-site expertise and a global network of research labs and personnel to deliver the phosphate results you need.

Phosphate Mining Offerings

Interested in frothers or collectors for phosphate mining? Learn how Nalco Water can help you meet your recovery and grade targets so you can improve efficiency and meet KPIs.

Frothers

Collectors

_

Flotation 360™

Mineral processing optimization can feel like a moving target. Changing ore, an incorrect formulation or failing to balance recovery and grade can impact your bottom line. But Nalco Water has your solution: Flotation 360. This digital technology helps you maximize productivity and optimize your flotation circuit performance.

Optimize your circuit with the predictive capabilities of Flotation 360 to help:

- Improve performance to increase recovery and profitability

- Enhance visibility of potential impacts of future ore changes, allowing for mitigation of any challenges in advance

- Optimize reagent dosing and chemical consumption, improving the total cost of operations

- Reduce maintenance challenges such as float cell valve failures, and spend less time manually troubleshooting

Nalco Water Scale-Guard™

Scale-Guard Helps Phosphoric Acid Plant Increase Annual Production by 54%

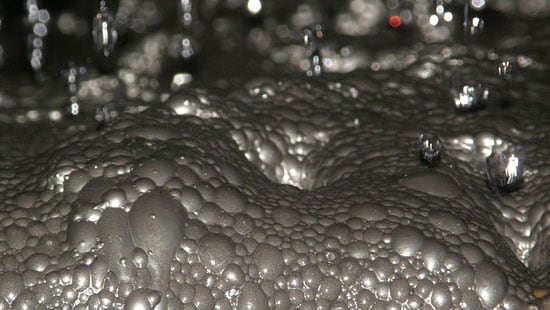

In phosphate processing operations, calcium sulfate scale is a daily cost of doing business. The scale results in lost evaporator efficiency, lost production time due to cleanings, increased cleaning-related expenses and cleaning-related safety challenges.

Nalco Water partnered with a US-based phosphoric acid plant to help minimize scale build-up. By deploying SCALE-GUARD EP310, Nalco Water helped the plant increase annual production by 54%, as well as decrease cleaning time and intensity.

Phosphate Mining Solutions

Nalco Water delivers phosphate processing solutions tailored to your unique needs.